Reliability

long-term stable and repeatable results

Time

less calibration effort

Quality

control of moisture, density, grammage and temperature

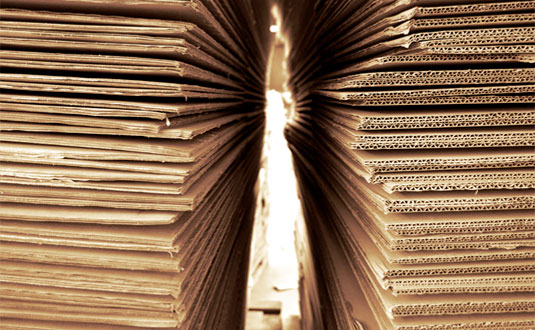

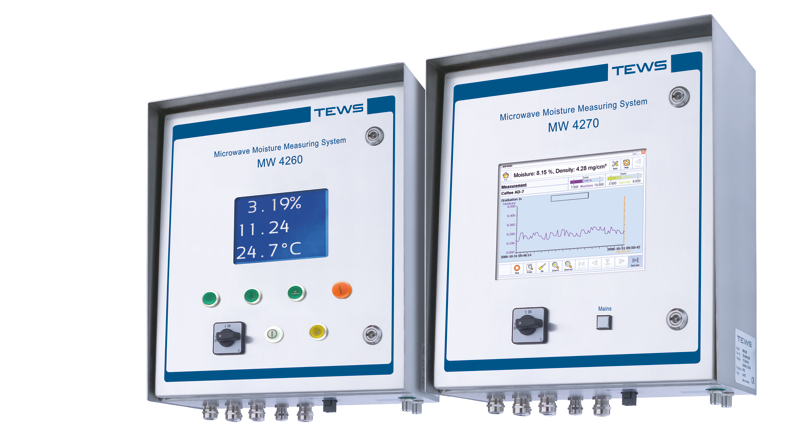

Measurably better - No matter whether paper, cardboard, or corrugated board our high-performance solutions are simple: we provide patented microwave technique tied to passion driven services. Why? The answer is as simple as our solutions: to improve the production process of our clients. Or, in other words: to help our clients to achieve better results.

Our solutions have been developed and designed hand-in-hand with the paper and cardboard industry and, therefore, fulfill all requirements in terms of reliability and precision.

The TEWS method enables paper and cardboard companies to gain high-precision data about the moisture content and density of their products. It’s a one-stop-shop without any sample preparation to optimize the whole production process in terms of cost savings and quality control.

Water Matters.

Product quality and -efficiency can be significantly optimized by controlling the moisture content in almost all process steps. Managing the moisture of paper and cardboard is a key factor to achieve better results. TEWS patented solutions deliver high precision results. It's what matters when it comes to company goals and how to achieve them faster.

- Fast Inline Measurement – The continuous moisture measurement at top-speed helps to cope with changing ambient process conditions and there is no need to wait long time on the results of spot checks.

- Improving Operating Efficiency – With our measurement results operators can utilize their advanced machines at an optimum and reduce downtimes and waste to a minimum.

- Warp-control – By checking the moisture of the single layers of paper before they are joined for the cardboard in combination with systems that effectively apply water the board flatness is significantly improved by the same time as the speed is increased thus resulting in a significant productivity gain. A key word in this context is “dimensional stability“.

- Product Quality – A precise moisture level is decisive for the quality. And that, in turn, satisfies your customers and reduces their claims.

- Optimizing Margins – Knowing the exact water content of cellulose bales helps avoid buying water instead of cellulose – in other words: It avoids paying the price of cellulose for additional water.

It Takes Two.

TEWS patented two-parameter measuring solutions enable the paper and cardboard industry to work with high precision data in both ways at the same time. Data that relate to the moisture content of paper and cardboard products as well as their density. Knowing the grammage of paper and carboard products during the manufacturing process leads to even better results in terms of product quality and -efficiency.

- Detecting Splice – Measuring the density or paper grammage online enables the operator to reliably detect splices. Grammage control and splice detection in one application – that is unique.

- Quality Control – For quality control reasons, the grammage of the paper must be measured at the end of the paper production process. Microwave technology replaces expensive and aging measuring cells based on radioactive sources, which also cause a lot of paperwork and administration due to strict regulations.

- Sheet Counting – Counting the number of paper or cardboard sheets at the end of the production line

Areas of Application.

Learn More About Our Patented Solutions.

How Can We Help You?