What can we do for you...

- Are you facing challenges with the stability and reliability of inline controls, affecting the accuracy of your data?

- Do you still rely heavily on manual labor for moisture measurements in the lab or find the need to frequently recalibrate your measurement systems?

- Is the time-consuming nature of hourly or daily controls impacting your operational efficiency?

- Have incorrect moisture level measurements significantly slowed down your plant’s performance?

- Are you experiencing increased energy costs due to difficulties in identifying the optimal moisture content in your product?

- Are you encountering obstacles in rejecting products with elevated moisture levels or foreign particles due to challenges in accurately identifying their content?

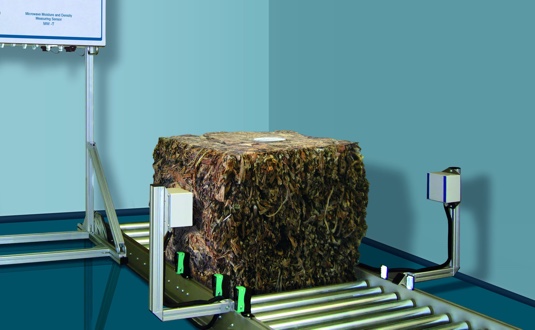

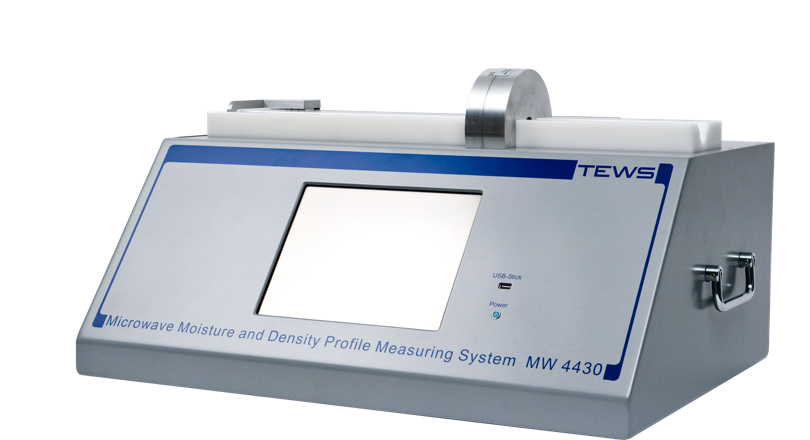

With the TEWS method, you can effortlessly access precise data on the moisture content and density of your products, working closely alongside the tobacco industry to meet all the essential requirements for quality control issues. Say hello to highly accurate moisture readings in line process or in laboratory that saves you money and ensures top-notch quality control.

Time

faster –in the lab due to readings within milliseconds

Quality

control - from the tobacco bale to the finished cigarette

Amortization

year – in a GLT

Let's work together to find solutions and drive success. Contact us now to discuss your specific needs and goals. Your journey to improved efficiency and profitability starts here.

It Takes Two.

Discover TEWS' patented two-parameter measurement solutions designed to empower tobacco companies with precision in both moisture content and density data. By obtaining precise data during tobacco production, you can enhance product quality and efficiency significantly. Explore how TEWS' innovation revolutionizes tobacco industry processes for superior results.

- Cost Control – Achieve cost efficiency with accurate and uniform weight distribution profiles for optimal tobacco use in cigarette production.

- Safe Products – Ensure product safety through automatic ejection of cigarettes containing foreign particles in the tobacco.

- Quality – Experience precise positioning of aromatic capsules and maintain the integrity of filter rods.

- Weight Control – Enhance weight control with exact and consistent determination of tobacco weight per cigarette.

They Trust Us

Explore the stories of our successful partners and envision your own path to success. Get inspired, take action, and create your own success story with TEWS solutions

White Paper

Download our White Paper about saving energy during the drying process.

How Can We Help You?

We invite you to connect with us. Please complete the form , and we will reach out to you promptly. Your inquiries and collaboration are of utmost importance to us. We look forward to assisting you