Energy

savings – due to improved dryer control

Time

faster –in the lab due to readings within milliseconds

Quality

control – of finished products like pet food pellets

Measurably better - No matter whether it is about compound feed or pellets, aqua feed, or pet-food, our high-performance solutions are simple: we provide patented microwave measurement technology tied to passion driven services. Why? The answer is as simple as our solutions: to improve the production process of our clients. Or, in other words: to help our clients to achieve better results.

Our solutions have been developed and designed hand-in-hand together with the feed and Petfood-Industry and, therefore, fulfill all requirements in terms of reliability and durability.

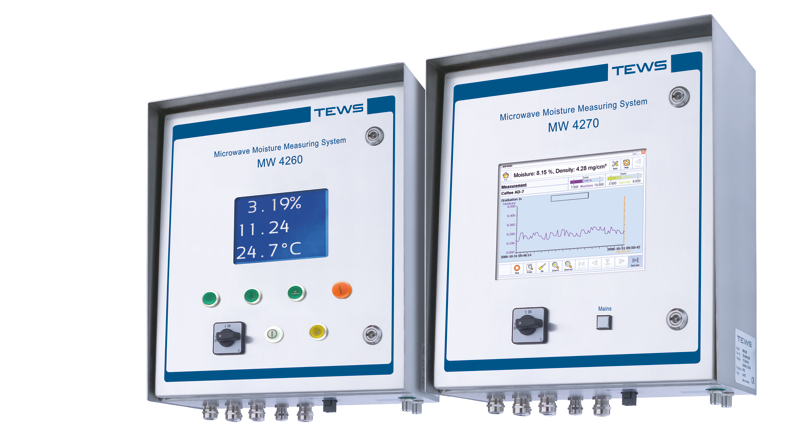

The TEWS method enables feed and Petfood-Companies to gain high-precision data about the level of moisture content and density of their products. It’s a one-stop-shop without any sample preparation to optimize the whole production process in terms of cost savings and quality control.

Water Matters.

Product quality and -efficiency can be significantly optimized by controlling the moisture content in almost all process steps. Managing the moisture of feed and Petfood as well as its ingredients is a key factor to achieve better results. TEWS patented solutions deliver high precision results. It's what matters when it comes to company goals and how to achieve them faster.

- Fast Inline Measurement – The continuous moisture measurement helps to cope with changing ambient process conditions and there is no need to wait long time on the results of spot checks.

- Point of Measurement – TEWS sensors can be used even under harsh environmental conditions with vibration, dust, EX-Zones

, and temperatures up to 45°C.

, and temperatures up to 45°C. - Plant Efficiency – With our measurement results operators can utilize their advanced machines at an optimum and reduce downtimes and waste to a minimum.

- More Profit– Precise data of water content lead to precise prices.

- Energy Efficiency – Precise information about moisture allows optimization of drying processes, prevents over-drying and leads to lower energy costs.

- Storage Efficiency – Precise compliance with the recommended water content prevents mold, avoids fungal infection or early degeneration and increases shelf live.

- Product Quality – Ensuring the optimum growth and health of the animals.

It Takes Two.

TEWS patented two-parameter measurement solutions enable feed and Petfood producing companies to work with precise data in both ways at the same time. Data that relate to the moisture content of feed, Petfood and their ingredients as well as their density. Knowing the bulk density of feed and pet-food during the manufacturing process leads to even better results in terms of product quality and efficiency.

- Mass Flow and Balance Check – Accurate density information being used to assure constant filling levels e.g. in bags and to avoid overfilling or to heavy products.

- Quality Control – Securing homogenity of your products.

Areas of Application.

Learn More About Our Patented Solutions.

How Can We Help You?